OUR SERVICES

Fire-Extinguishers

According to the fire code, extinguishers need to be tested every year and recharged (refilled) every six years. Fire-Alert offers on-site extinguisher inspections and refills for most makes and models. If you are unsure, here are some helpful hints:

- Check the pressure gauge, if it’s fallen below the functional level, it’s time to refill.

- If your unit does not have a gauge, have it tested by a Fire-Alert Expert immediately.

- Have your extinguisher checked annually.

- Even if you have not used your extinguisher, it needs to be filled every six years.

- If you do use it, refill it as soon as possible after use.

A trained and certified expert from Fire-Alert will reliably perform maintenance and recharge your fire extinguishers on-site.

Fire extinguishers should be maintained at regular intervals (at least once a year), or when specifically indicated by an inspection. A fire extinguisher inspection is intended to give maximum assurance that an extinguisher will operate effectively and safely. It includes a detailed examination and any necessary repairs, recharging or replacement. It will normally reveal the need for pressure testing (hydrostatic testing) of an extinguisher to ensure the cylinder is safe to use.

Steps to performing an annual inspection for fire extinguishers:

- Have a checklist handy with the date of each fire extinguisher inspection and follow each step until complete. Be sure to mark the date of inspection on the inspection tag of your fire extinguisher.

- Your extinguisher should not be blocked by any equipment, coats or objects that may interfere with access in case of an emergency.

- Always check to ensure that the pressure of the unit is at the recommended level by checking the gauge to confirm that the needle is in the green zone which will show that the pressure is right where it should be.

- Make sure the nozzle or other parts of the extinguisher are not obstructed in any way.

- If your portable fire extinguishers have a pin and tamper seal, check to see if they are intact and undamaged.

- Check for dents, rust, leaks or any sign of abuse or wear. Take a damp rag and wipe off any gunk or chemicals that may have accumulated on the device.

- Shake your extinguisher to prevent the powder from settling to the bottom.

During our maintenance service, if the results show that the extinguisher is damaged or needs recharging our experts at Fire-Alert will immediately replace it. Functional fire extinguishers are required throughout the premises. It is the most important tool against fire; however, if it is not kept in good working condition it will not be useful in times of need.

To ensure that the fire extinguisher works in the event of a fire, you should follow these guidelines:

- First and foremost, make sure the fire extinguisher is in a location that makes it readily accessible.

- Ensure that the fire extinguisher is set up properly for easy handling, and that nothing is obstructing access to any parts of it, including the hose.

- Be certain that the fire extinguisher is adequately charged at all times, and ready for use. Regularly check the pressure dial to see if it needs to be charged.

- Verify that the pull pin is properly secured within the handle and held in place by the tamper seal.

- Examine the fire extinguisher for any cracks, dents, or rust on its shaft which might hinder its performance.

- Check that there is a visible instruction label on the fire extinguisher, and that it is legible in case of emergency.

- Make sure that no modifications were made to the fire extinguisher that might affect its performance level.

Emergency Lighting and Exit Signs

Emergency lighting and exit signs must also be tested according to the fire code, emergency lighting and exit signs need to be tested every year. Fire-Alert offers on-site testing to determine if units are still functioning properly. Some examples of what is required is listed below.

- Emergency lighting shall be provided in:

- Exits

- Principal routes providing access to exit in an open floor area

- Corridors used by the public

- Underground walkways

- Public corridors.

- Emergency lighting required in Section (1) shall be provided from a source of energy separate from the electrical supply for the building.

- Lighting required in Section (1) shall be designed to be automatically actuated for a period of at least 30 min when the electric lighting in the affected area is interrupted.

- Illumination from lighting required in Section (1) shall be provided to average levels of not less than 10lx at floor or tread level.

- Where self-contained emergency lighting units are used, they shall conform to CSA C22.2 No. 141, “Unit Equipment for Emergency Lighting.

EXIT SIGNS

- Every exit door shall have an exit sign placed over or adjacent to it if the exit serves:

- A building more than 2 stories in building height,

- A building having an occupant load of more than 150, or

- A room or floor area that has a fire escape as part of a required means of

- Every exit sign shall:

- Be visible from the exit approach,

- Have the word EXIT or SORTIE displayed in plain legible letters, and

- Be illuminated continuously while the building is occupied.

- Exit signs shall consist of:

- red letters on a contrasting background or contrasting letters on a red background, with the letters not less than 114 mm high and having a 19 mm stroke, if the sign is internally illuminated, and

- white letters on a red background or red letters on a contrasting background that is white or a light tint, with letters not less than 150 mm high and having a 19 mm stroke, if the sign is externally illuminated.

Fire Hose Testing

Fire-Alert experts test and inspect hoses to the most current NFPA standards and current Fire Code rules.

When your equipment ages, the materials they are constructed from can degrade. Hydrostatic testing and visual inspections are the best way to know if your equipment is up to the job. Your fire hoses require hydrostatic testing when they have been in service for five (5) years, then every three (3) years afterwards. Allow Fire-Alert to inspect your hoses yearly and to perform hydrostatic tests when required, to give you, your employees and building occupants protection and peace of mind.

Fire-Alert will inspect supply beds, pre-connects, hose bundles and rolls. All hoses shall be pre-inspected prior to testing. All couplings will be checked for damage/slipping. Gaskets will be checked for damage or if they are missing. The outer jacket will be checked for damage. If for any reason, one of the above is found, the hose is removed and marked out of service.

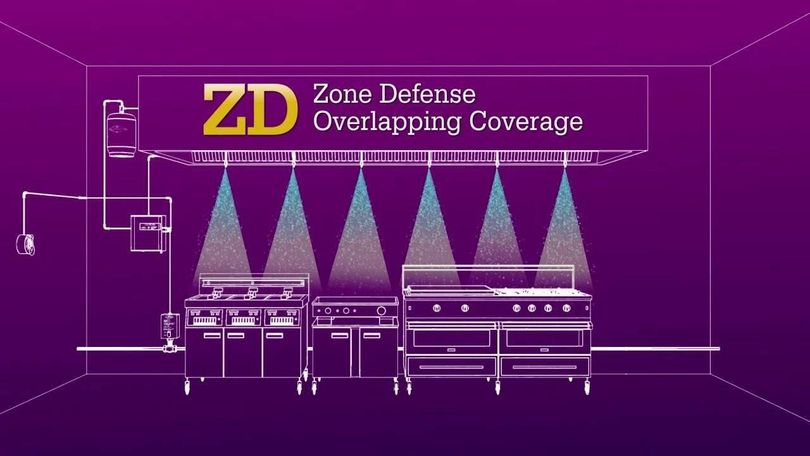

Fire Suppression Systems

We service Kitchen Hood Suppression and industrial Systems made by Range Guard, Buckeye, Sentinel and are authorised distributors to sell and install Amerex and Protex systems as per Ontario Fire Code 2.6.1 and NFPA 96 standards.

The AMEREX® Kitchen Protection (KP™) Fire Suppression System

KP is a staple in commercial kitchens around the world. To meet NFPA guidelines and ensure quality, Amerex stringently tests this product with Underwriters Laboratory to meet UL 300, Standard for Fire Testing of Fire Extinguishing Systems for Protection of Commercial Cooking Equipment. KP is designed to accommodate the needs of building and restaurant owners who utilize restaurant fire suppression systems to protect their valuable property and ensure the safety of the people working in the kitchens. From fine dining to fast food chains, the Amerex Kitchen Fire Protection system has the components to meet your needs with competitive pricing while never sacrificing quality.

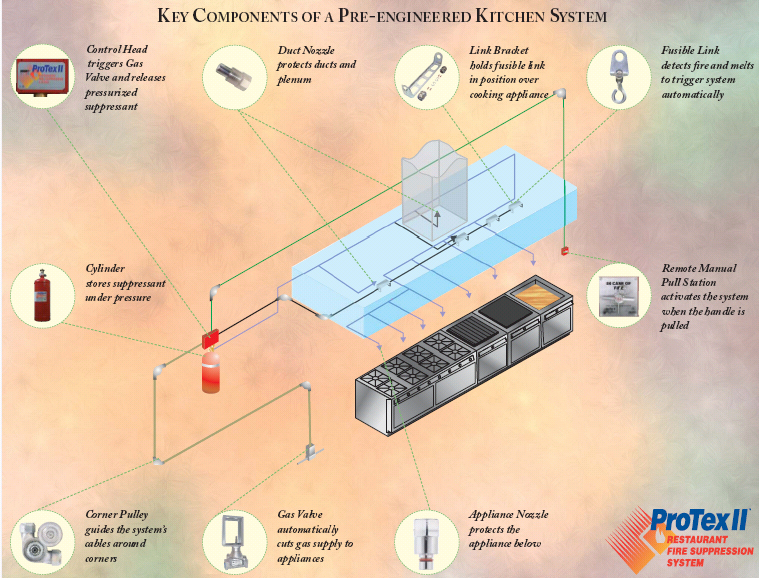

The ProTex II system offers breakthrough technology in the industry’s most flexible and effective fire suppression system.

The fire extinguishing agent is a potassium carbonate-based water solution that knocks the flame down, cuts off air to the burning grease and cools the hazard area to help ensure the fire stays out.

The ProTex II system has been tested and approved in accordance with the ul testing standard for kitchen cooking areas, Standard ul-300. ProTex II authorized distributors must be extensively trained in system design, installation and maintenance.

ProTex II system components undergo continuous research and development, which result in continuous improvements to virtually every aspect of the system. Your ProTex II system will provide affordable, effective protection for your cooking area.

FireAlarm/Sprinkler Inspections

We partner with well trained experts in our industry to provide these services to our customers. All work is performed in accordance with NFPA.

We take great pricde in equipping homeowners with all necessary fire safety devices to ensure the well-being of families across the nation.

CLIENT TESTIMONIAL

STAFF WAS VERY KNOWLEDGABLE

“ Had lost of questions regarding fire safety. staff was very knowledgeable and friendly”

- Bassel Kadri